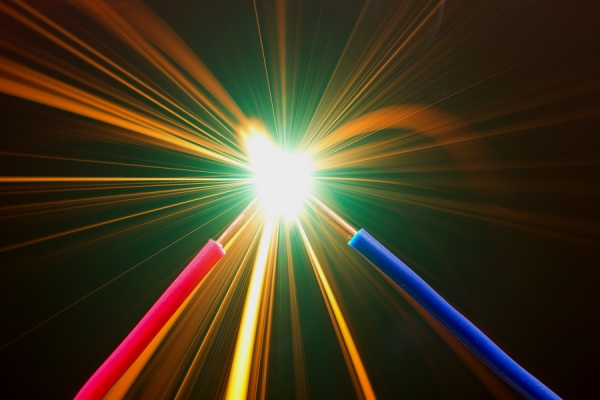

Arc Flash Explosions

Every day in the United States five to 10 arc flash explosions occur in electrical equipment. Anyone exposed to such explosions is at significant risk for death or serious injury.

Arc flash is described by the National Fire Protection Association as “a dangerous condition associated with the release of energy caused by an electric arc.” A reduction of the insulation or isolation distance between energized components is responsible for this condition.

For example, a tool that is inserted or accidentally dropped into a breaker or service area, or other objects that are left behind, may compromise the distance between energized components.

Incidents may occur when a worker fails to ensure that equipment has been properly de-energized prior to servicing or inspection. Arc flash incidents typically occur in applications exceeding 120 volts.

Serious damage to equipment is a likely outcome in an arc flash incident. Sometimes affected equipment is so badly damaged that replacement is the only option. And, of course, the human body is equally capable of being destroyed or irreversibly damaged, with no replacement option.

The following arc flash safety reminders from Square D Products, a well-known producer of electrical equipment, can help company better protect their employees:

- Establish a written electrical safety program with clearly defined responsibilities covering all of your company’s electrical safety policies, including lockout/tagout, internal safety policies and responsibilities for electrical safety.

- Have an engineering firm conduct an electrical system analysis to determine the degree of arc flash hazard present at your workplace. The analysis will define the type of personal protective equipment (PPE) that your workers must use while performing any work when energized parts are exposed.

- Conduct arc flash safety training for all employees. It should be specific to the hazards of arc flash, arc blast, shock and electrocution. Ensure adequate personal protective clothing and equipment is on hand.

- Ensure the proper tools are on hand for safe electrical work. This includes insulated voltage-rated hand tools and insulated voltagesensing devices that are properly rated for the voltage application of the equipment to be tested.

- Any electrical equipment that is likely to require examination, adjustment, servicing or maintenance while energized must have arc flash warning labels posted in plain view. Such equipment includes switchboards, panel boards, industrial control panels, meter socket enclosures and motor control centers.

- Appoint an electrical safety program manager. This should be a well-organized, responsible person who is familiar with electrical code requirements and other safety issues.

- Maintain all electrical distribution system components. Modern, properly adjusted over-current protective devices that are properly maintained are able to detect an arcing condition almost instantly and clear the fault quickly. This capability significantly reduces the amount of incident energy that is released.

- Finally, maintain and update all electrical distribution documentation. This is especially critical when expanding or revising facilities.